Smart customized yacht equipment

Since 1983, Akerboom Yacht Equipment has been at the forefront of crafting custom yacht equipment, renowned for its superior quality and enduring reliability. Our commitment to continuous improvement and innovation has led to a novel approach in the design, production, servicing, and enhancement of bespoke yacht equipment.

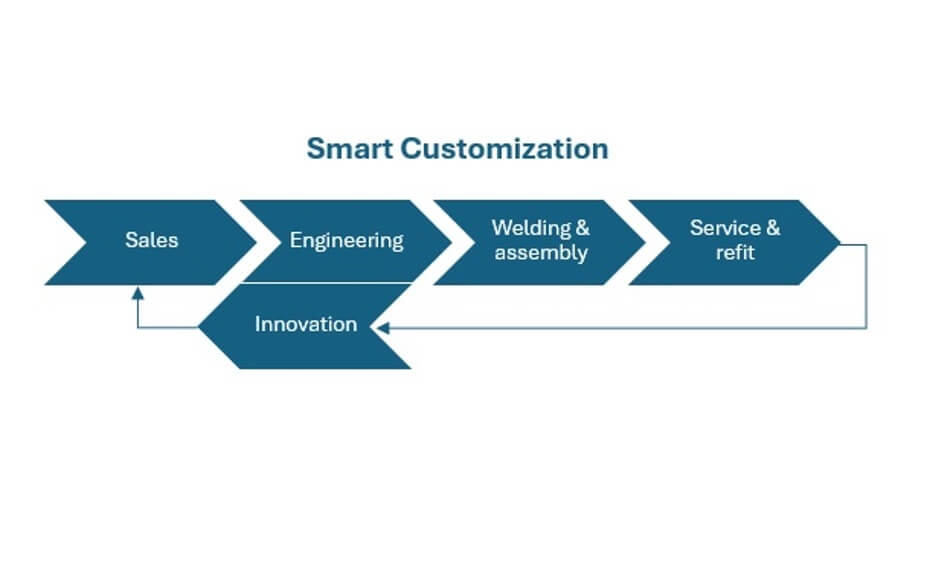

In parallel industries, the adoption of modular design, smart customization, and configure-to-order (CTO) strategies has been pivotal in developing competitive product families. Initially, sectors characterized by high production volume but low product diversity, such as automobile manufacturing, achieved success. Subsequently, equipment suppliers catering to markets with low production volume but high product diversity have also thrived. Over the past eight years, Akerboom Yacht Equipment has successfully incorporated smart customization across all its product families, delivering tailored, one-off solutions that meet the unique needs of each client.

Akerboom, an original equipment manufacturer (OEM) and system developer of yacht equipment, has instituted a development roadmap focused on smart customization to enhance customer value and mitigate risks of failure across all product ranges. For each product family, Akerboom conducts a modular function deployment (MFD) analysis, which distinguishes between generic modules and client-specific modules.

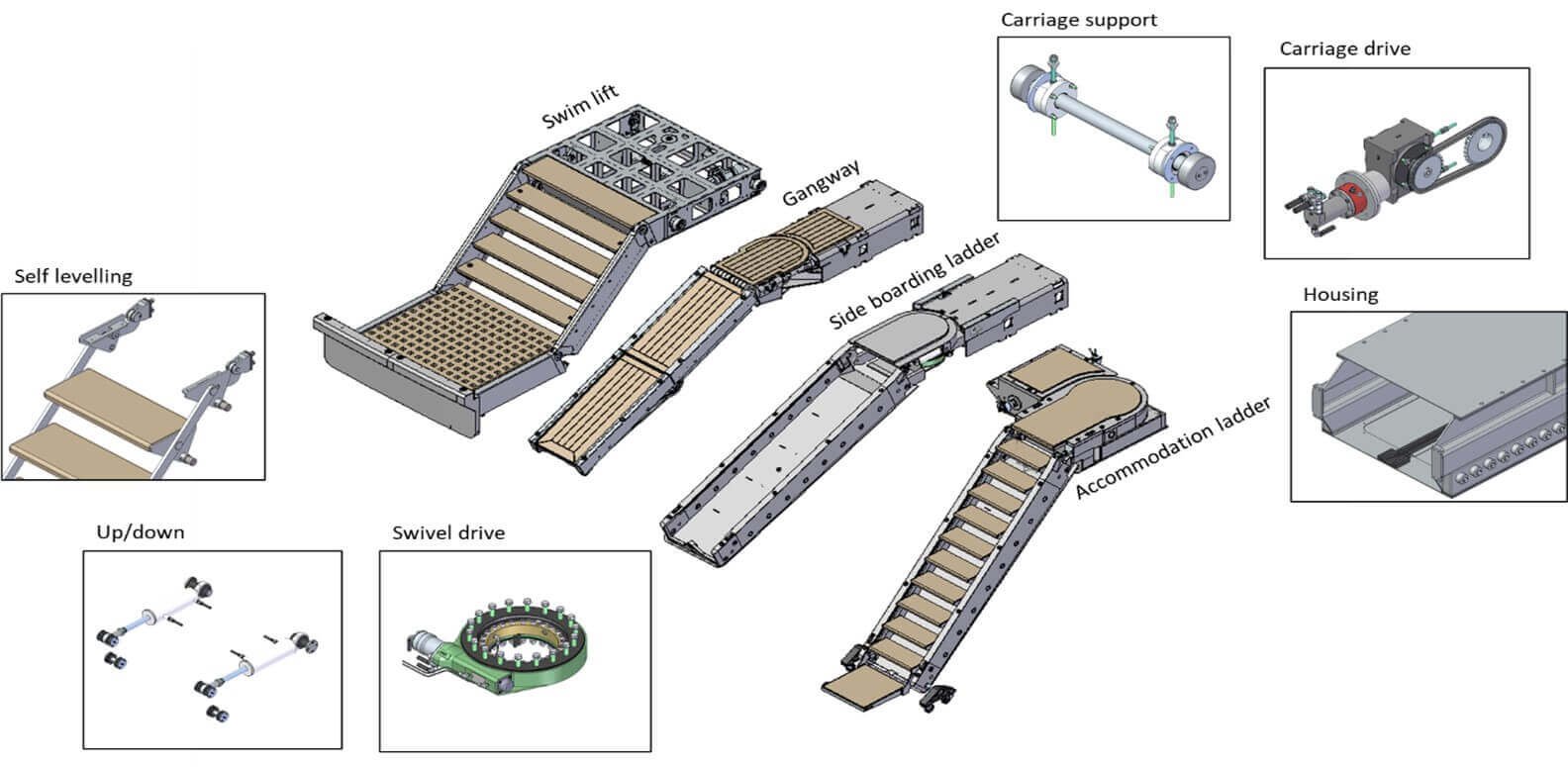

Generic modules consist of components that are standardized through the consistent use of reliable and proven technology. These modules, often not visible to the client or of peripheral interest to the owner, are designed to perform flawlessly. Examples of generic modules include hydraulic cylinders, bearings, and hinges. As illustrated in the following image, for the product family of boarding equipment, Akerboom has identified several generic modules: carriage support, carriage drive, housing, self-levelling stairs mechanism, up/down cylinders, and the swivel drive.

Employing generic modules offers numerous benefits. By leveraging proven technology, Akerboom Yacht Equipment ensures high and consistent quality levels, making its products exceptionally reliable. Throughout their lifecycle, both in use and in service, Akerboom gathers extensive feedback on the performance of these generic modules. This feedback fosters a broad expertise in both corrective and preventive maintenance, allowing Akerboom to build a robust knowledge base and deliver optimal service. Armed with this knowledge, Akerboom continuously refines and innovates these modules. As an OEM, Akerboom ensures that upgraded generic modules are designed to be interchangeable, facilitating future service and refit operations. Additionally, the use of generic modules has enabled Akerboom to develop a cost-effective and well-organized supply chain, which significantly reduces lead times for service and refit projects.

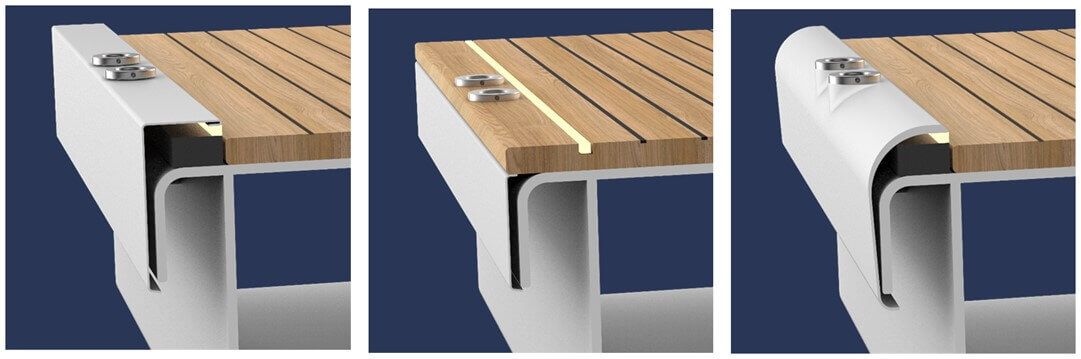

Client-specific modules are those components within a product family that cater to individual preferences and requirements. For example, the dimensions and aesthetic design of a yacht often necessitate client-specific modules. In the Akerboom product family of doors, platforms, and hatches, the construction is always customized to integrate seamlessly into the yacht’s design. In the boarding equipment product group, clients can select the width of a gangway, such as a wider option to accommodate a wheelchair. Additionally, choosing the external shape of the gangway enhances the customer experience by ensuring a design that complements the yacht, as illustrated in the subsequent image.

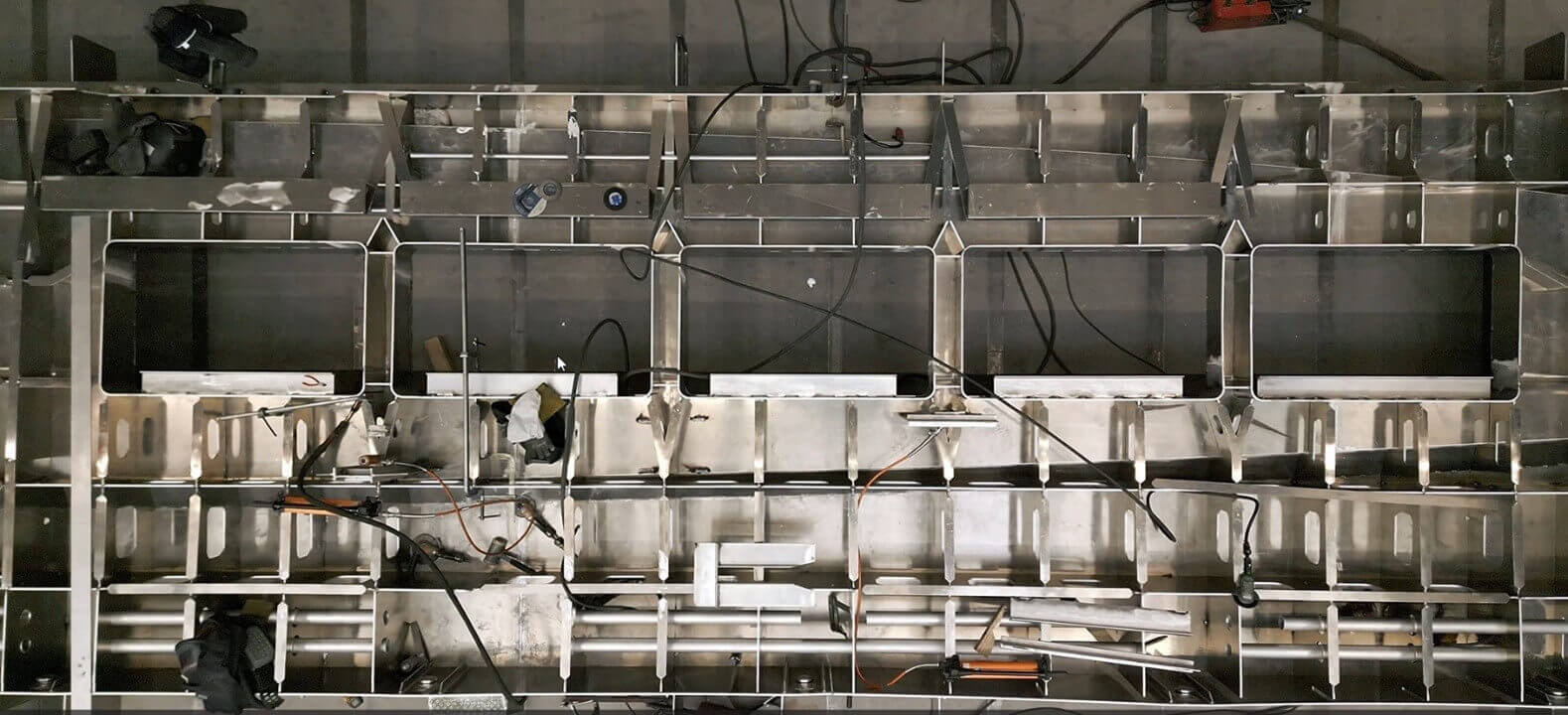

In client-specific modules, the advantages of modular construction and smart customization are again realized. These modules allow customer specifications regarding dimensions and design to be met, while employing uniform production processes and base materials. Although the constructions of doors, platforms, and hatches are tailored to each client, standardizing certain aspects, such as material thickness in aluminium and construction patterns, offers significant benefits. In production, this standardization allows welding procedures to be uniform across client-specific modules, making the deformation caused by welding heat more predictable. The accompanying image illustrates how the portholes and their dimensions are customized to client specifications, yet the base materials, welding processes, and construction patterns remain standardized.

Utilizing client-specific modules, it is crucial to leverage accumulated knowledge and design rules, which Akerboom has honed through extensive experience with customer requirements. This expertise enables the rapid calculation and quotation for a wide range of products through smart customization.

When customizing a product family on a modular basis, it is essential to balance the scale of the modules—they should be neither too large nor too small. As illustrated in the image below, the comparison between Duplo and Lego is apt: finer details result in a superior product, but also introduce more modules and complexity into the system. Akerboom’s long history of engineered-to-order solutions has been instrumental in refining the scope and number of modules per product family. This approach has been validated through a quality function deployment (QFD) analysis and corroborated by a review of order history.

In the smart customization process at Akerboom, it is acknowledged that not everything can be encompassed within generic and client-specific modules; each project invariably includes a component that requires engineering-to-order. Akerboom boasts a robust engineering team that, supported by the modular design framework, focuses on achieving 100% quality in project completion. As a preferred co-maker for custom-built projects for Feadship, Akerboom’s engineering capabilities are well-equipped to deliver unique solutions.

Innovations in these special solutions often contribute new client-specific modules or even generic modules incorporating standardized parts to the product family. Through such developments, Akerboom Yacht Equipment continues to expand client possibilities within the smart customization process, enhancing both product functionality and diversity.

For more information, please mail akerboom@ayeholland.nl