In Command: From Trustworthy Remotes to Realtime Feedback

For decades, Akerboom has delivered reliable wireless r [...]

For decades, Akerboom has delivered reliable wireless remote controls for superyacht equipment—robust, waterproof, and capable of operating up to four components simultaneously. But in environments where timing and feedback are critical, even robust performance must be paired with clear communication.

Traditional systems offered minimal user feedback, and built-in safety protocols or hydraulic delays could cause hesitation. Was the system responding? Had a fault occurred? These questions often required a trained eye—or trial and error.

The next step was clear: transform the user experience from uncertainty to insight.

Introducing Real-Time Feedback with Integrated Display

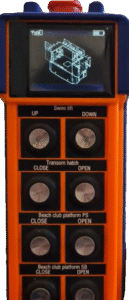

Akerboom’s latest generation wireless remote control features a fully integrated display, offering real-time operational data at a glance. The new interface shows exactly which equipment is active, which actions are being executed (including movement angles), and—crucially—provides immediate safety or fault diagnostics when operations are interrupted.

Already implemented aboard Feadship yachts and available for both new builds and refits, this innovation allows captains, crew, and service teams to operate with greater confidence and clarity. During commissioning, the interface can even be tailored to reflect yacht-specific workflows and preferences, offering a customised, intuitive onboard experience.

This isn’t just an upgrade. It’s a redefinition of how yacht equipment is monitored, understood, and controlled.

More Than a Remote: A Control Ecosystem

The innovation doesn’t stop with the remote. Today’s Akerboom control systems form a complete ecosystem:

-

-

-

-

- Cabinet Interfaces: High-resolution displays in control cabinets provide system-wide status, I/O readings, and error logs—everything technicians and engineers need at their fingertips.

- Mobile Mirroring: Control interfaces can be mirrored to mobile phones or tablets (without enabling control, for safety reasons), offering additional visibility and support from anywhere on board.

- Custom Configurations: From entry-level PLC displays to full control suites with error and process logging, Akerboom’s systems can be scaled to fit any configuration or integration need.

-

-

-

All of these developments reflect a deliberate shift from reactive operation to proactive insight. They allow faster diagnostics, improved safety, and smoother workflows—reducing downtime and elevating user trust.

Engineering Transparency. Delivering Control.

At Akerboom, innovation is not confined to mechanics—it extends to usability. By integrating real-time feedback, custom user interfaces, and modular upgrade paths, Akerboom’s control systems are setting a new standard in operational transparency.

Whether you’re installing a new gangway, upgrading an existing hatch system, or integrating controls across a full platform package, the ability to stay in command—at all times, with full clarity—has never been more essential.

Interested in upgrading your control systems or integrating Akerboom equipment into your next build or refit?

Contact us at: yachtservices@ayeholland.nl