Innovation in Action: Akerboom’s Fully Integrated Cranes

The design, construction, and installation of yacht cra [...]

The design, construction, and installation of yacht cranes demand precision, reliability, and innovation. At Akerboom, we deliver fully integrated crane systems, covering everything from design and testing to installation, commissioning (IBS), and crew training. Our latest crane project illustrates how our engineering expertise and in-house capabilities enable us to provide safe, space-saving, and class-approved solutions for the most demanding superyacht designs.

How It Started: A Design Challenge at the Forefront

Every project begins with understanding the unique requirements of the yacht design. In this case, the General Arrangement (GA) called for innovative crane integration at the bow of the vessel—an area where space is tight, and precision is critical. The initial request focused on integrating the crane’s interface (IF) into the yacht’s structure.

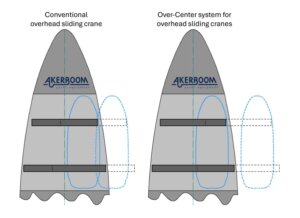

However, we soon identified that the current crane system on the market could not meet these requirements. The limited space and slender bow design meant that traditional crane beams would not provide sufficient reach to safely lower tenders overboard without the risk of hull contact. This challenge led to the decision to redesign the crane while retaining as many proven components as possible. The goal: maximize reliability and ensure parts availability without compromising on innovation.

The Innovation: Overcenter System and Beam Utilization

Central to our new crane concept is the overcenter system, which allows the crane beam to extend further overboard without the need for a telescopic mechanism. To explore this idea, our lead engineer first tested the overcenter geometry using technical LEGO—a hands-on way to validate the concept’s feasibility before moving to digital engineering models.

Central to our new crane concept is the overcenter system, which allows the crane beam to extend further overboard without the need for a telescopic mechanism. To explore this idea, our lead engineer first tested the overcenter geometry using technical LEGO—a hands-on way to validate the concept’s feasibility before moving to digital engineering models.

The result was an innovative internal handover mechanism that shifts the beam beyond the vessel’s centerline, increasing usable beam extension from 45% to 75% while maintaining structural integrity. This allows the tender to be safely launched from either port or starboard, eliminating the need for multiple cranes or complex telescopic solutions. The compact design also helps yacht builders maximize deck space.

Recognizing the novelty and value of this solution, Akerboom applied for a patent—our second active patent in the current innovation portfolio.

In-House Testing: Ensuring Reliability Before Installation

After finalizing the design, the crane system underwent rigorous mechanical and software testing in-house at Akerboom. Every function—from structural movements to the custom control program—was verified under controlled conditions. This ensures that when the crane is installed on board, it is already a fully operational, proven system, despite being a new concept.

Class Approval and Crew Training: Supporting Safe and Effective Operations

Before installation, the system was officially inspected and approved by class society DNV (RO DNV), demonstrating compliance with the highest industry standards. The cranes were then transported to the yacht and installed after the vessel’s launch. The assembly was completed, and the cranes were successfully commissioned.

The final step in our delivery process is training the yacht’s crew to operate the crane system safely and effectively. Before the yacht departs from the Netherlands, our engineers provide comprehensive hands-on training, ensuring the crew is confident in both standard operations and emergency procedures.

Akerboom’s Commitment: More Than Just Equipment

This project exemplifies Akerboom’s commitment to delivering not just equipment, but complete solutions. Our integrated approach—from design and innovation to installation and training—ensures that every crane we deliver meets the highest standards of reliability, safety, and performance.

By continuously investing in engineering innovation and in-house testing capabilities, Akerboom enables yacht builders and owners to overcome complex technical challenges while optimizing space, safety, and usability on board.